Tape when duct tape was invented one of it s nick names became 100 miles per hour tape because pit crews would use it to tape slightly damaged sheet metal on race cars.

How ti epoxy sheet metal behind rust holes.

I used a piece of pvc pipe a vice mount miniature metal break and body hammer kit.

Easy to do and really strong.

When water contacts bare metal rust forms on the surface of the metal.

Get it as soon as thu oct 1.

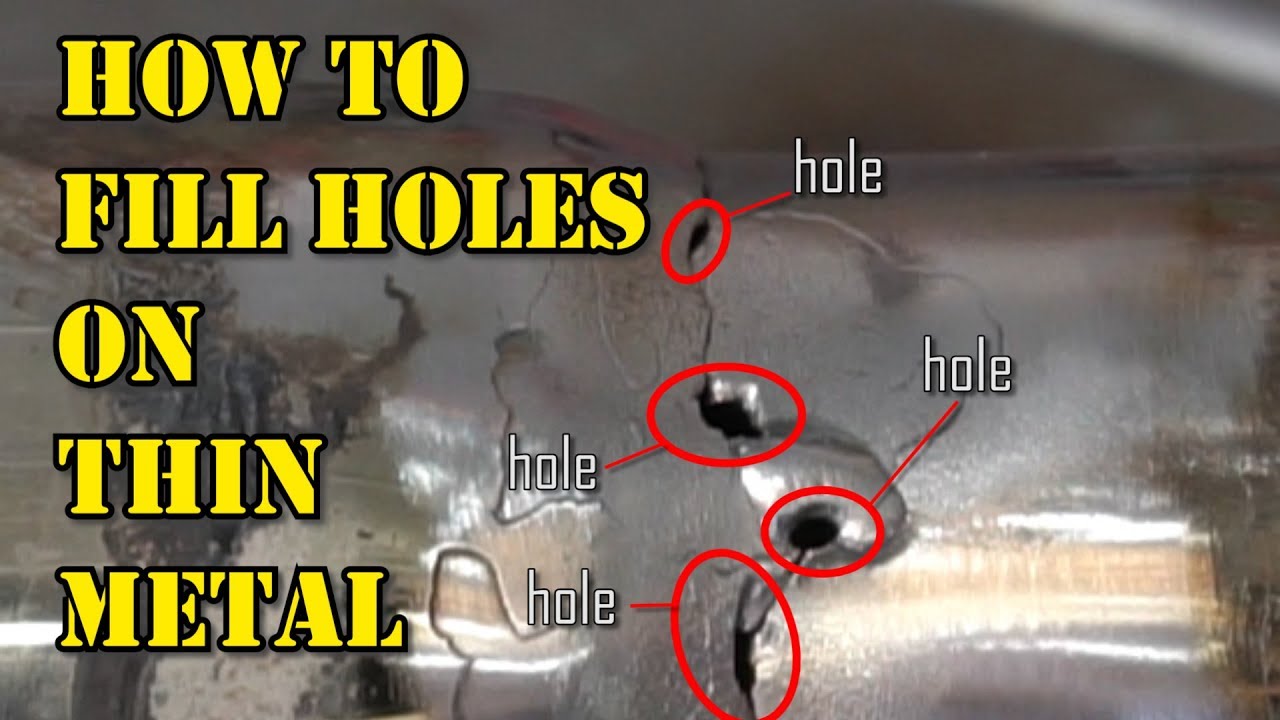

This is one way out of many to repair rust holes.

If you can t see the hole through the backer you can shine a light directly on the back or from behind the hole and it should help you see better for tracing.

Start by drilling a small hole in the center of a backer and lay it over the rust.

Best deal on goodyear air hose check this out https amzn to 3b5cjvy how to fix a hole without welding no warping.

Once the damaged metal has been fully exposed you can continue scraping and rough sanding the surrounding metal to an area at least 1 to 2 inched past the weak metal.

You can then trace the hole on to the backer with a marker.

1 16 of over 2 000 results for epoxy for metal repair best seller in metal filled epoxies.

Whether you re dealing with a small piece of sheet metal or something valuable like a car you can fix it.

Coat the area inside the hole thoroughly with miracle paint to prevent further rusting then make a patch of 3 layers of fiberglass mat soaked in miracle paint and apply it over.

J b weld 8265s original cold weld steel reinforced epoxy 2 oz.

If left unchecked rust can eat through the metal resulting in a hole.

If you know how to weld take advantage of your tools for a longer lasting repair.

By filling in holes you stop rust in its tracks and ensure the metal lasts longer.

Epoxy weld is perfect for plugging holes in thin metal and in many instances the results can be a permanent fix to the problem.

Repairing rust or a rust hole on metal without welding requires a material that bonds and is as strong as metal.

4 7 out of 5 stars 6 173.

After slicing the patches out with a cutoff wheel next came the bending hammer and dolly session until the patches matched the holes and fit snug and flush into the flanged seat.

A rust hole compromises the structural integrity of the metal.

I then used the templates to trace out the patch panels on some sheet metal.