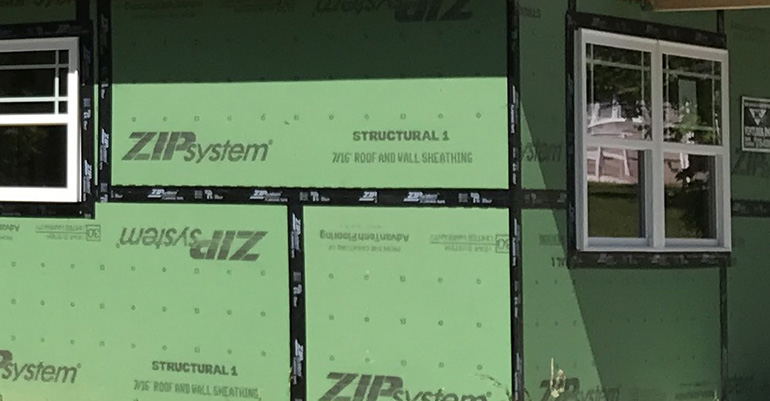

Zip system roof and wall sheathing panels are oriented strand board osb structural panels with built in protective overlays that eliminate the need for building wrap or roofing felt.

How to attach siding to zip sheathing.

In this tutorial you will learn.

Install the panels tape the seams with hubers zip system tape and the building is rough dried in.

Zip system sheathing is a type of osb.

It s basically the same 7 16 inch osb wall sheathing bonded to either a 1 2 inch r 3 6 or 1 inch r 6 6 polyiso foam panel.

This type of sheathing does not add significantly to a wall s strength but can greatly increase its insulation value.

Rigorously engineered to streamline continuous air and water barrier performance in structural roof and wall assemblies it has changed the way teams build.

Our easy to install zip system sheathing and tape streamlines the weatherization process that delivers moisture and air protection with a water and air barrier.

Nails or other code recognized fasteners used to attach zip system sheathing to supporting framing members may occasionally penetrate beyond the face of the zip system panels.

The definition of an overdriven fastener.

Once the sheathing seams have been taped with zip system tape the sheathing functions as a water resistive barrier wrb as well as an air barrier.

By creating the integrated sheathing category over a decade ago zip system sheathing and tape replaced the need for housewrap on walls and felt underlayment in roof applications.

Cladding weight shall include all materials supported by the fasteners on the exterior side of the foam sheathing e g.

Let s take a look at overdriven fasteners and their effect on zip system sheathing.

And one thing we ve been noticing is the frequent use of a new exterior sheathing product called zip system.

Rigid foam and cellulose fiber panels may be attached directly to wall studs or masonry walls under or over structural sheathing depending upon nailing requirements or in some cases over existing siding before re siding.

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/19496796/siding_illo.jpg)